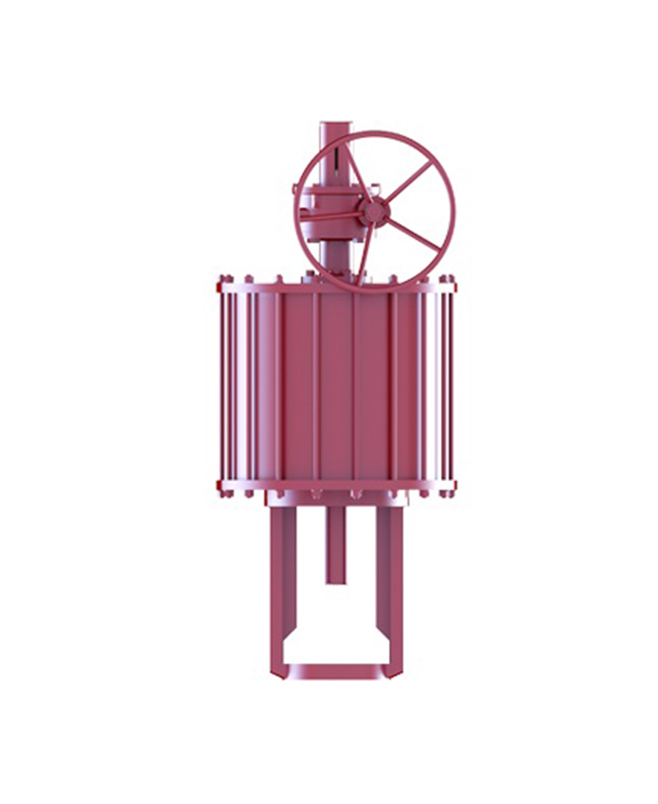

PISTON ACTUATOR

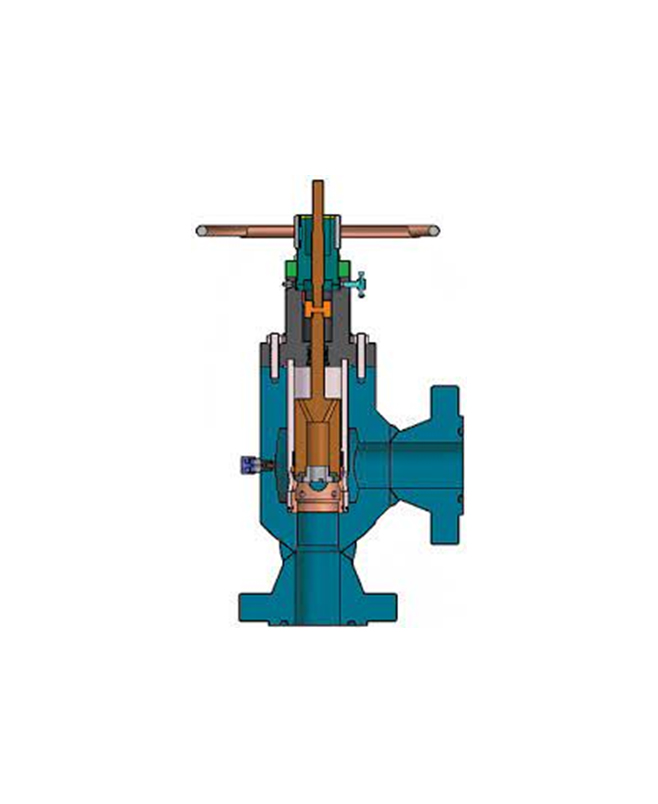

Exploring the realm of mechanical engineering, various components and devices play unique, intricate roles. Among these crucial elements is the pneumatic piston actuator, a device that has become a crucial aspect in a wide range of applications across numerous fields. Have you ever found yourself wondering about the function, purpose, and relevance of these devices? Let’s dive right in and explore the riveting world of pneumatic piston actuators.

Types of Pneumatic Piston Actuators :

Broadly, there are two main types of pneumatic piston actuators: Single-acting and Double-acting.

Single-acting actuators utilize the force from the compressed air to create movement in one direction, and a spring to return the piston to its original position. These are common in applications where the return to a “fail-safe” state is critical.

On the other hand, Double-acting actuators use the force from compressed air for both the ‘push’ and ‘pull’ motions. This type is common in circumstances where precise control and powerful movements are necessary.

Product Description

SPECIFICATIONS :

Performance

- Long stroke.(maximum 600mm).

- Large Thrust. Reliability.

- Low hysteresis.

- Light weight.

- Easy maintenance

Scope of Design

- Maximum thrust : 150 to 6238kgf.

- Cylinder bore : 100 to 400mm.

Working Condition

- Maximum working pressure : 8kgf.

- Maximum working temperature : 90°C.

- Minimum working temperature : -40°C.

Actuation

- Double acting : Series 1700.

- Spring acting : Series 1600D spring opposite acting.

Series 1600R spring return acting.

Features:

- Long-stroke (max. 600mm)

- High thrust

- Good Reliability

- Low hysteresis

- Lightweight

- Easy maintenance

- Double acting and spring return

- A wide selection of accessories are available

Reviews

There are no reviews yet.