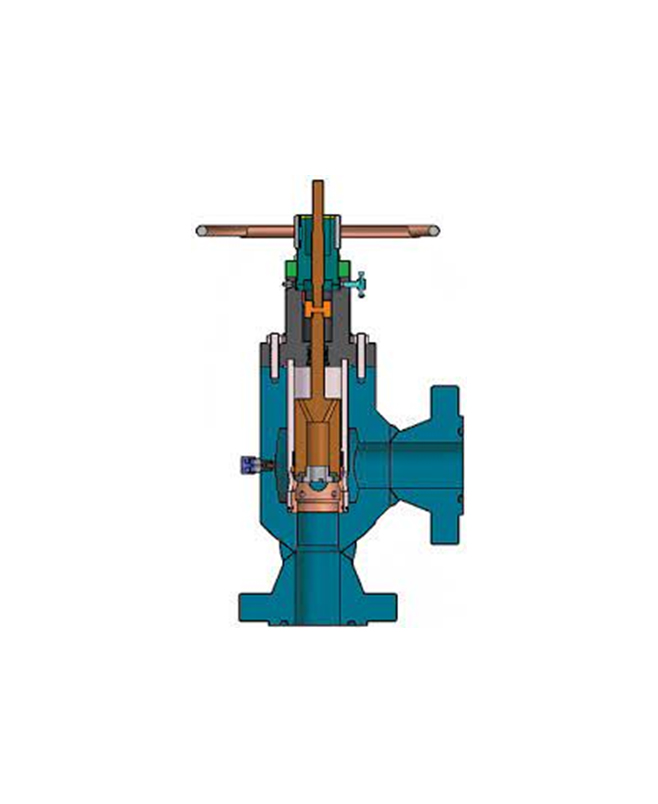

CHOKE VALVE

SPECIFICATIONS :

| Valve Size | : 1 13/16– 13 5/8 |

| Pressure Class | : ANSI /ASME 900, 1500, 2500 and API 2000, API 3000, API 5000, API 10000 AND API 15000 |

| End Connection | : RF / RTJ / BW |

| Flow Characteristics | : Concentric cages / Disc stack |

| Operator | : Pneumatic Actuator / Hydraulic/Electric Actuator |

| Material | : Carbon Steel / Stainless Steel / Duplex / Alloy Steel |

| Operating Temperature | : Standard / High |

| Leakage Class | : ANSI FC70-2 |

| Design Standard | : API 6A / ASME SEC VIII/ ASME 16.5/ ASME B16.34 |

| Face to Face Standard | : ASME B16.10 |

| Certification | : EN 10204 3.1 – 3.2 / 2014-68-EU PED |

Understanding choke valves, their types, considerations, and applications are crucial to the successful and safe operation of oil and gas processes. Despite its seemingly simple design, a choke valve plays a noteworthy role in maintaining necessary pressure and flow control both in industrial and domestic processes. A reminder to every operator or homeowner – always ensure you have quality choke valves in place, as they can be the difference between a smoothly running system and a disastrous scenario

While choosing Choke valves, many factors come into play such as material, size, operation mechanism, and working environment. Remember to keep in mind the following tips:

- Material: Choke valves should be selected based on the type of oil/gas or fluid they will be dealing with.

- Size: The size of the valve must match the dimensions of your piping system. Having a mismatched size can cause leaks or malfunctions.

- Mechanism: Depending on whether you need manual control or a fixed flow rate, you’ll select either adjustable or positive choke valves.

Features :

- Durable service life of PVI Choke Valve, delivered by a simple yet robust design.

- Low life cycle cost of PVI Y Type thus resulting in enhanced resistance to all sort of erosive production liquid.

- Easy inspection and maintenance serviced by removal of reserved internals while the PVI Valves is under maintenance.

- PVI Y Type’s delivers operational safety and confidence.

- Guaranteed by 100 percent shut-off.

- Thoroughly controlled environmental impact guided by the reduced noise and vibration effects.

- Enhanced pressure recovery performance delivered by ultimate bean and disk design.