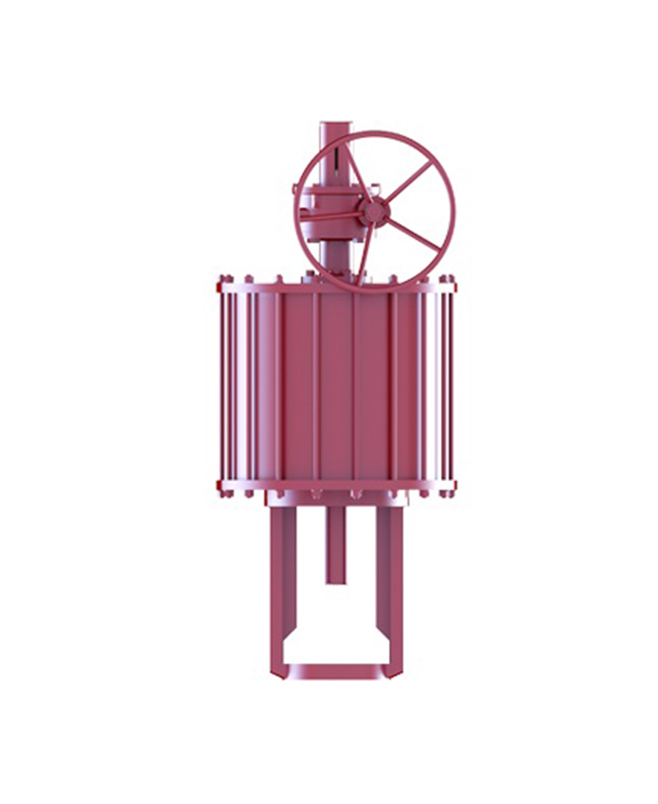

GLOBE CONTROL VALVE

Globe Control Valves are more than just another valve in your system; they play an essential role in regulating the flow of fluid, providing precision control when needed most. With due consideration and regular maintenance, these valves can offer a reliable solution for your equipment’s fluid control needs while ensuring smooth industrial operations.

Globe Control Valves are usually classified into three major types based on their disc and seat design:

- Z-type or Z-body Globe valves: This design adopts a direct path, reducing pressure losses while offering simplified construction and convenient maintenance.

- Y-type Globe Valves: These valves contain a seat and stem at an angle of 45 degrees to the pipe axis. They offer lowered resistance to flow in comparison to the Z-type, in addition to being perfect for high-pressure applications.

- Angle Globe Valves: The inlet and outlet of these valves lie at a 90-degree angle, ensuring more straightforward installation and improved efficiency.

Product Description

SPECIFICATIONS

| Valve Size | 1″ – 24″ |

| Pressure Class | ANSI 150 / 300 / 600 / 900 / 1500 |

| End Connection | RF / RTJ / BW |

| Flow Characteristics | Equal Percentage / Linear / Quick Opening |

| Operator | Pneumatic Actuator / Electric Actuator |

| Material | Carbon Steel / Stainless Steel / Duplex / Alloy Steel |

| Operating Temperature | Standard / High |

| Leakage Class | ANSI FC70-2 |

| Design Standard | ASME B16.34 |

| Face to Face Standard | ASME B16.10 / ANSI/ISA 75.08 |

| Certification | EN 10204 3.1 – 3.2 / 2014-68-EU PED |

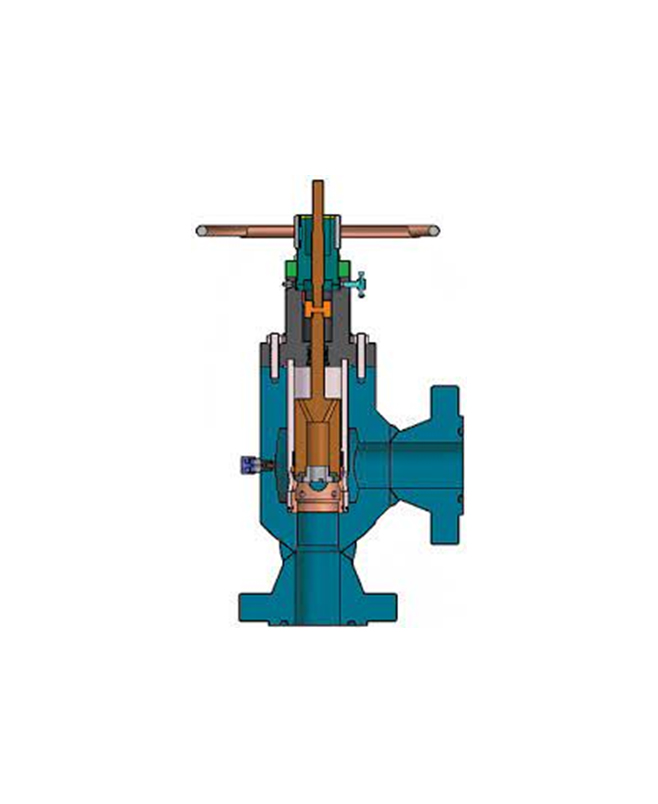

Features :

| 1. The actuator selection is automatic. |

| 2. The instrumentation on the valve is pre-assembled. |

| 3. Easy maintenance. |

| 4. Renewable seats. |

| 5. Available with metal and soft seats. |

| 6. Blow out proof stem. |

| 7. Strengthened stem packing is the default. |

Reviews

There are no reviews yet.