Products

PISTON ACTUATOR

INDUSTRIAL VALVES

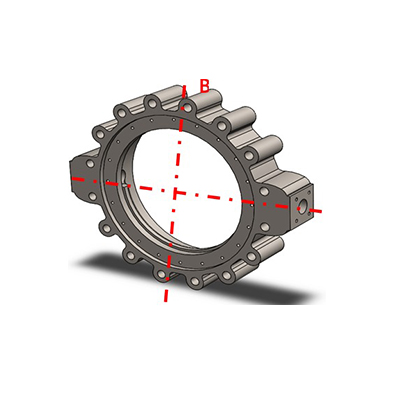

Ultimate Guide to Trible Offset Butterfly Valves

Discover the outstanding features and advanced technology behind the Trible Offset Butterfly Valves. Designed by PONNAR VALVES INDIA PRIVATE LIMITED, these valves offer unparalleled performance and reliability. Perfect for industrial applications, our triple offset butterfly valves ensure precise flow control, minimal maintenance, and extended service life.

Key Features of Trible Offset Butterfly Valves

Our Triple Offset Butterfly Valves are engineered to provide superior sealing and exceptional durability. Here are some of the key features:

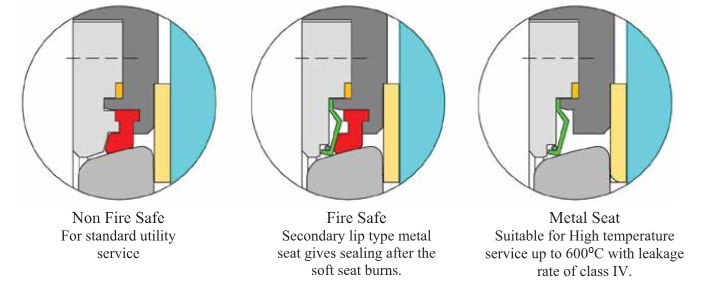

- Triple Offset Design: The uniquely structured trible offset principle ensures zero leakage and robust sealing performance, making it ideal for critical applications.

- High-Performance Materials: Constructed from premium-grade materials, these valves are resistant to corrosion, wear, and high-temperature conditions.

- Easy Maintenance: Our butterfly valves are designed for easy maintenance and long-term reliability, reducing operational downtime.

- Wide Range of Applications: Suitable for various industries including petroleum, chemical, energy, and water treatment.

How Trible Offset Butterfly Valves Work

The trible offset design of these butterfly valves incorporates three separate offsets. The right-angle conical sealing surface ensures tight shutoff, while the cam action and right-angle rotation prevent rubbing and minimize wear and tear. This advanced mechanism enhances the valve’s lifecycle, ensuring greater cost-efficiency and performance.

Applications and Benefits

The Trible Offset Butterfly Valves by PONNAR VALVES INDIA PRIVATE LIMITED are perfect for:

- Oil and Gas Industry

- Chemical Processing Plants

- Water and Wastewater Treatment

- Power Generation Facilities

With our triple offset butterfly valves, benefit from:

- Extended service life

- Enhanced sealing capabilities

- Reduced operational costs

- High reliability and safety

Why Choose PONNAR VALVES INDIA PRIVATE LIMITED

PONNAR VALVES INDIA PRIVATE LIMITED has been synonymous with precision and quality in the valve manufacturing industry. Our commitment to innovation and customer satisfaction ensures that you receive top-quality products backed by exceptional service. Trust our expertise for all your valve needs and experience the difference in performance and reliability.

Don’t miss out on the unmatched performance of our Triple Offset Butterfly Valves. Order yours today and elevate your industrial operations with the best in valve technology!

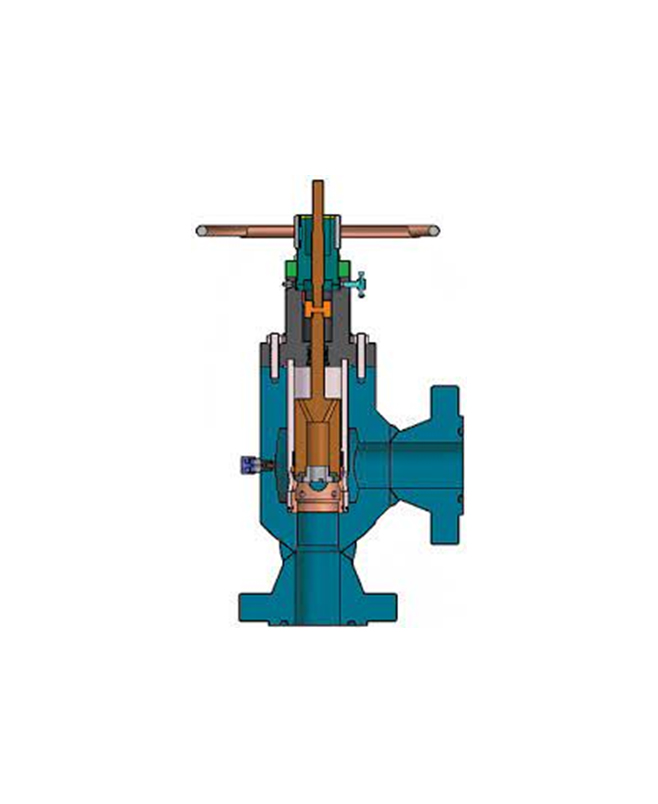

Globe valves

A Globe valve is a linear motion valve and are primarily designed to stop, start and regulate flow. The disk of a Globe valve can be totally removed from the flowpath or it can completely close the flowpath.

Conventional Globe valves may be used for isolation and throttling services. Although these valves exhibit slightly higher pressure drops than straight=through valves (e.g., gate, plug, ball, etc.), they may be used where the pressure drop through the valve is not a controlling factor.

Because the entire system pressure exerted on the disc is transferred to the valve stem, the practical size limit for these valves is NPS 12 (DN 300). Globe valves larger than NPS 12 (DN 300) are an exception rather than the rule. Larger valves would require that enormous forces be exerted on the stem to open or close the valve under pressure. Globe valves in sizes up to NPS 48 (DN 1200) have been manufactured and used.

Globe valves are extensively employed to control flow. The range of flow control, pressure drop, and duty must be considered in the design of the valve to avert premature failure and to assure satisfactory service. Valves subjected to high-differential pressure-throttling service require specially designed valve trim.

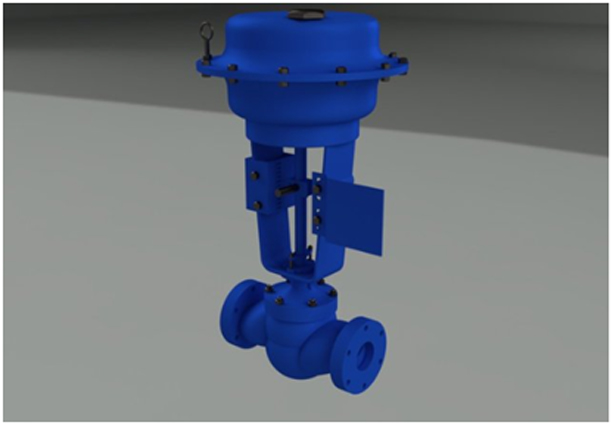

Diaphragm actuator

The diaphragm actuator belongs to the class of pneumatic actuators and is the most widely used compared to electric, hydraulic and manual actuators. Due to its simple design and reliability, this type of actuator is primarily used in the industrial sector (chemical and petrochemical industry) and in power plants.

Features

Low overall height

Design of leg posts and diaphragm casing allows for maximum strength with minimum overall height.

Long service lift

Diaphragm casing are rugged, thick-walled, internally coated steel construction providing stability and corrosion protection.

High trust capability

Molded and reinforced diaphragm permits higher pressure to provide maximum thrust for a given diaphragm size.

High dynamic stability and frequency response

Shallow casing means reduced volume, thereby minimizing response time.

Reduced hysteresis

Multi-spring design provides diaphragm stability and improves operational repeatability.

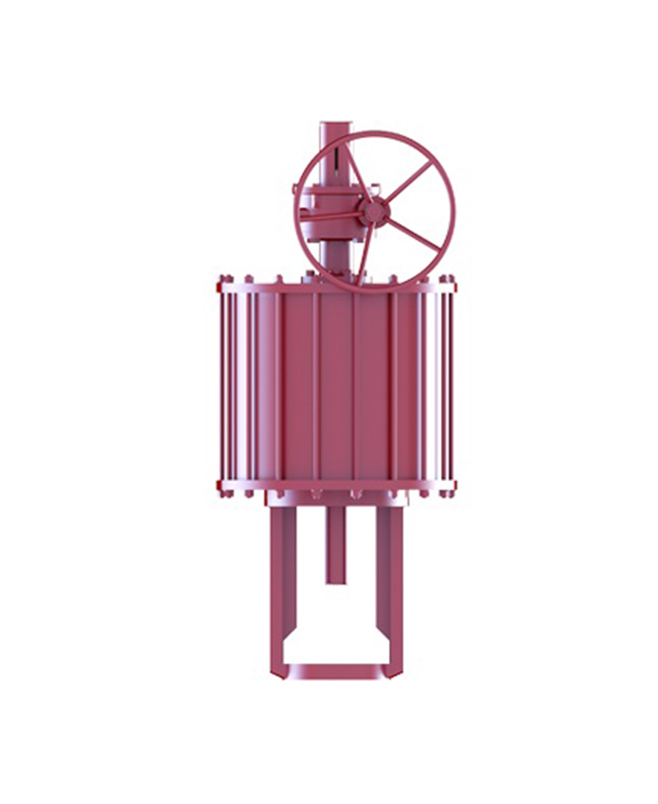

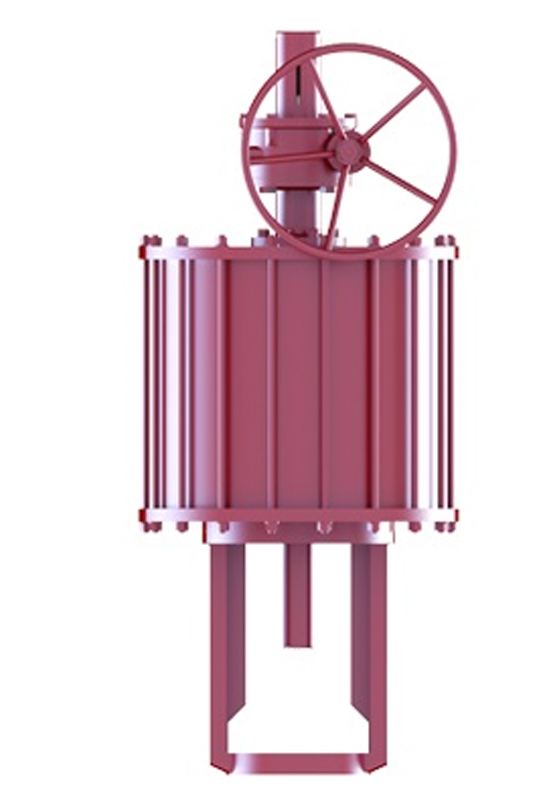

Pneumatic Cylinder Actuator

PONNAR linear double-acting pneumatic piston actuators are designed for high force applications. When combined with a positioner or a two-position control signal, PONNAR actuators can be used for throttling or on/off control. PONNAR actuators will always require a volume tank in order to hold a fail position.

Features

- Double acting and spring return

- Spring to open or close

- 100mm (4″) to 1066mm (42″) diameters

- Pneumatic forces to 300000 lbf (1300 kN)

- Spring forces to 700000 lbf (3000 kN)

- Wide operating temperature range

- Material options: mild steel, aluminium and stainless steel

- Designed specifically for bespoke customer applications

- Double and triple pistons available for valve actuation in restricted areas

ANCILLARIES

- Interconnection mountings

- Bridgeworks and connectors

- Mechanical – manual overrides with hand wheels

- Limit-switches, sensors and junction boxes

- Positioners, position indicators and pointers

- Customer required specifics